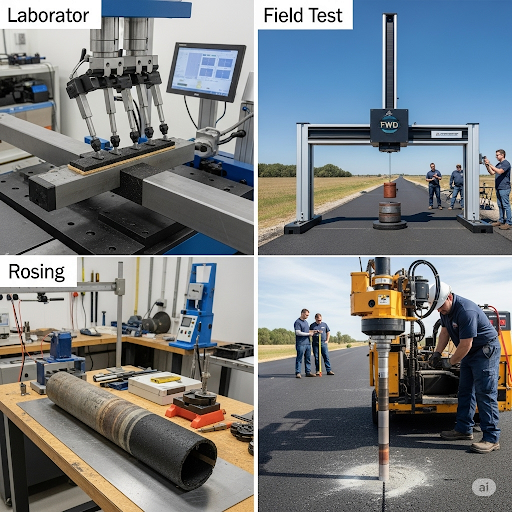

Laboratory and Field Evaluation Methods

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Laboratory Tests Overview

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're starting with laboratory tests for bituminous mixes. Why do you think laboratory tests are crucial in pavement engineering?

They help us understand how the materials will behave under stress and real conditions.

Exactly! We use various tests like fatigue testing, rutting resistance, and dynamic modulus tests. Each serves a unique purpose. Can anyone think of a reason why fatigue testing would be particularly important?

To simulate the wear and tear from repeated traffic loads, right?

Correct! Fatigue testing gives us insights into how long a pavement will last before showing cracks. These tests help us design more durable pavements. Can someone explain what dynamic modulus testing involves?

It measures how stiff the mix is under cyclic loading conditions.

Yes, it’s crucial for predicting behavior under real traffic loads! Let’s summarize what we learned: laboratory tests are vital because they simulate conditions to predict pavement performance accurately.

Field Performance Evaluation Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s transition to field evaluation methods. Why do you think field evaluations are as important as lab tests?

Field evaluations give us real-world data about how the pavement performs over time.

Absolutely right! One common tool we use is the Falling Weight Deflectometer. Can anyone explain how it works?

It applies a load to the pavement and measures the resulting deflection to assess structural capacity.

Well said! This deflection helps us infer about the underlying layers' health. Another method is visual distress surveys. What do you think those entail?

Basically, inspecting the surface for cracks, ruts, and other forms of damage?

Correct! These surveys can quickly identify the need for maintenance. Lastly, we also use core sampling to check material properties. Why might this be beneficial?

It allows us to actually see and assess the material quality within the pavement.

Exactly! Field evaluation methods complement laboratory findings for a holistic view of pavement performance. In summary, they are key for practical insights and informed maintenance decisions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section elaborates on laboratory tests focused on fatigue testing, rutting resistance, and dynamic modulus, as well as field evaluation techniques such as Falling Weight Deflectometer (FWD) assessments, visual surveys, and Pavement Condition Index (PCI). These evaluations are crucial for ensuring the longevity and reliability of pavement structures.

Detailed

Laboratory and Field Evaluation Methods

This section explores critical laboratory and field evaluation methods essential for assessing the mechanical performance of bituminous mixes, which form the backbone of flexible pavements. It reflects on standardized tests and field procedures that inform engineers about the condition and expected behavior of pavements under actual service conditions.

12.9.1 Laboratory Tests

Laboratory tests are crucial for understanding the performance characteristics of compacted samples. These include methods such as:

- Fatigue Testing: Evaluates the mix's ability to withstand repeated loads without failing, simulating real traffic conditions.

- Rutting Resistance Testing: Assesses how well a mix resists permanent deformation under repeated loading through specific tests.

- Indirect Tensile Strength: Estimates the tensile strength of the mix, which is critical for understanding crack development under load.

- Dynamic Modulus Testing: Determines the stiffness of the bituminous mix under cyclic loading, a key indicator in pavement design applications.

12.9.2 Field Performance Evaluation

Field evaluations complement laboratory findings by providing real-world insight into pavement performance. Key evaluations include:

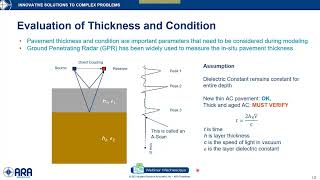

- Falling Weight Deflectometer (FWD): Measures the deflection of the pavement under a known load, which helps assess structural capacity.

- Visual Distress Surveys: Involves expert assessment of visible surface distresses to categorize pavement condition.

- Coring: Involves extracting cylindrical samples from the pavement to evaluate thickness, material quality, and compaction.

- Surface Condition Indices: Such as the Pavement Condition Index (PCI), provide a numerical representation of pavement health, guiding maintenance and rehabilitation decisions.

Overall, these evaluation methods are pivotal in enhancing our understanding of bituminous mixes and ensuring optimized performance in pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Laboratory Tests

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Fatigue testing, rutting resistance, indirect tensile strength, dynamic modulus.

• Conducted on compacted samples using standardized equipment.

Detailed Explanation

Laboratory tests are essential to assess the performance of bituminous mixes under controlled conditions. Some key tests include:

- Fatigue Testing: This evaluates how well a bituminous mix can withstand repeated loading without cracking. It simulates the stress a pavement will face over its lifespan.

- Rutting Resistance: This test checks how much a bituminous mix can deform under long-term loading, particularly in high-temperature conditions. The goal is to ensure that it can maintain its shape and not develop depressions due to traffic.

- Indirect Tensile Strength: This measures the strength of the bituminous mix indirectly by applying a load across a cylindrical sample. It helps predict how the mix will perform under stress.

- Dynamic Modulus: This measures the stiffness of the mix when subjected to various loading frequencies and temperatures, giving insight into its mechanical behavior under varying conditions.

These tests are performed on compacted samples to simulate actual pavement conditions more accurately.

Examples & Analogies

Think of laboratory tests as the training regimen for a professional athlete. Just as athletes undergo various drills to prepare for competition (e.g., sprinting for speed, weightlifting for strength), laboratory tests assess how bituminous mixes will perform under realistic pavement conditions. If an athlete is well-prepared, they can withstand tough competition; similarly, a well-tested mix can endure the stresses of traffic and environmental conditions.

Field Performance Evaluation

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Falling Weight Deflectometer (FWD) for structural assessment.

• Visual distress surveys and coring.

• Surface condition indices like Pavement Condition Index (PCI).

Detailed Explanation

Field performance evaluation is vital to understand how bituminous mixes perform in real-world conditions. Key methods include:

- Falling Weight Deflectometer (FWD): This device simulates the load of a passing vehicle by dropping a weight from a certain height and measuring the pavement's deflection. It helps assess the structural integrity of the pavement, indicating whether it can support traffic loads.

- Visual Distress Surveys: Professionals conduct on-site inspections to visually assess the condition of the pavement. They look for cracks, ruts, and other distress signs that indicate how well the pavement is performing.

- Coring: This involves drilling cylindrical samples from the pavement to analyze the materials and properties in-depth. It helps verify the effectiveness of the construction techniques used.

- Surface Condition Indices: The Pavement Condition Index (PCI) is a numerical scale that helps quantify the pavement's overall condition based on observed distress. This data is crucial for maintenance planning and resource allocation.

By combining these methods, engineers can form a comprehensive understanding of pavement performance over time.

Examples & Analogies

Imagine how a teacher assesses student progress. In the classroom, teachers may give written tests (like the FWD), observe students in group activities (like visual distress surveys), check homework assignments for understanding (like coring), and use report cards (like PCI) to track progress over the year. Just as teachers need multiple methods to gain a complete picture of student performance, engineers use various evaluation methods to understand how well the pavement is holding up over time.

Key Concepts

-

Laboratory Tests: Assess the mechanical properties and performance of bituminous mixes.

-

Field Evaluations: Provide real-world insight into the performance and condition of pavements.

-

Falling Weight Deflectometer: A non-destructive tool for structural assessment of pavement layers.

-

Visual Distress Survey: Assessment technique to identify visible surface distresses.

Examples & Applications

Using a Falling Weight Deflectometer to assess highway pavement to check if it's suitable for heavy truck loads.

Conducting a visual distress survey on a city road to determine the need for resurfacing.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For pavements that last, tests should be strong, fatigue and deflection, help hold on!

Stories

Imagine engineers at a construction site using the Falling Weight Deflectometer. They measure how well the pavement can stand up under loads, just like testing a bridge before cars drive on it.

Memory Tools

F-R-D-P: Fatigue, Rutting, Dynamic modulus, and Pavement Index - Remember these for pavement evaluation!

Acronyms

L-E-F

Laboratory tests yield Evaluation Factors - Lab tests (L) and Field tests (E) combine for (F) Full evaluation.

Flash Cards

Glossary

- Fatigue Testing

Testing that evaluates the performance of bituminous mixes under repeated loading to determine resistance to cracking.

- Rut Resistance

Ability of a bituminous mix to resist permanent deformation or ruts due to repeated traffic loads.

- Dynamic Modulus

Measure of the stiffness of bituminous mixes under cyclic loading conditions.

- Falling Weight Deflectometer (FWD)

A device used for measuring the deflection of pavement under a known load, assessing structural capacity.

- Pavement Condition Index (PCI)

Numerical score representing the overall condition of a pavement surface based on visual inspection.

Reference links

Supplementary resources to enhance your learning experience.