Rutting and Permanent Deformation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Rutting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss rutting, which refers to the permanent grooves or depressions in pavement surfaces caused by traffic over time. Can anyone tell me why understanding this concept is important?

It's important because it affects the lifespan and safety of roads!

Exactly! Rutting increases maintenance costs and compromises safety. Now, who can describe what actually causes rutting?

Is it due to the material flow under the weight of vehicles?

Correct! It occurs through densification and shear flow in the mix. Remember, the acronym **DPS** for Densification, Permanent deformation, and Shear flow to help recall this. This leads us to the next important aspect: the factors affecting rutting.

Factors Affecting Rutting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What do you think are the main factors that contribute to rutting in bituminous mixes?

Maybe the binder type plays a role?

Absolutely! The binder type and grade are crucial. Other factors include aggregate gradation, compaction quality, temperature, and overall pavement thickness. To remember these, just think of **B.A.C.T** - Binder, Aggregate, Compaction, Temperature. Can anyone expand on how temperature influences rutting?

Higher temperatures make the asphalt softer, so it deforms more easily.

Right! High pavement temperatures contribute significantly to permanent deformation. Let's move on to how we can test for rutting resistance.

Rutting Resistance Testing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To ensure pavement durability, specific tests are used to evaluate rutting resistance. What tests can you think of?

The Wheel Tracking Test!

Correct! The Wheel Tracking or the Hamburg Wheel Tracking Test simulates the conditions that lead to rutting. Other tests include the Repeated Load Triaxial Test and the Dynamic Creep Test. Each serves to mimic the stresses and conditions that asphalt will face over time. Let's summarize: who can list the tests discussed?

Wheel Tracking Test, Repeated Load Triaxial Test, and Dynamic Creep Test.

Perfect recap!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Rutting refers to permanent depressions in pavements due to the accumulated deformation of bituminous mixes under repeated traffic loads. The section delves into the mechanisms of rutting, factors affecting it, and various methodologies for rutting resistance testing.

Detailed

Rutting and Permanent Deformation

Rutting is identified as a permanent longitudinal depression in flexible pavements, typically observed in the wheel paths of vehicles, resulting from accumulated deformation due to repeated loading. This phenomenon primarily arises from the densification and shear flow within the bituminous mix, particularly prevalent at elevated pavement temperatures.

Mechanism of Rutting

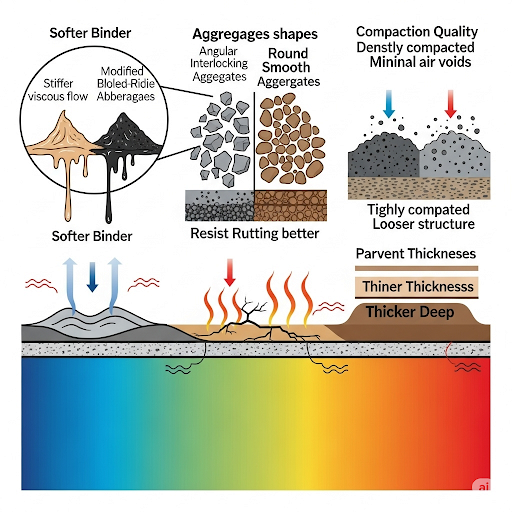

Rutting development is typically influenced by several factors, including:

1. Binder Type and Grade: Different grades of bitumen exhibit varying resistance to deformation.

2. Aggregate Gradation and Angularity: The size distribution and shape of aggregates impact the mix's ability to resist rutting.

3. Compaction Quality: Proper compaction techniques can mitigate rutting potential.

4. Pavement Temperature and Thickness: Higher temperatures lead to increased deformation, while thickness can provide additional resistance.

Rutting Resistance Testing

There are standardized tests to assess the ability of bituminous mixes to resist rutting, which include the following:

- Wheel Tracking Test (Hamburg Wheel Tracking): This test simulates vehicle wheel paths under heat and load conditions to evaluate rutting potential.

- Repeated Load Triaxial Test: It assesses the performance under controlled repeated loading.

- Dynamic Creep Test: It measures the deformation characteristics of bituminous mixes under dynamic loading conditions.

Understanding rutting and permanent deformation is pivotal for ensuring the longevity and safety of pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Rutting

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Rutting refers to the permanent longitudinal depression in wheel paths due to accumulated deformation under repeated loads.

Detailed Explanation

Rutting is a term used to describe indentations or depressions that form in the surface of a roadway, usually in the path where vehicles frequently travel. This occurs because of the pressure and weight of the vehicles that cause the road material to deform over time. Unlike other forms of deformation that can recover, rutting is termed 'permanent' because once the rut forms, it does not return to its original shape. This permanent change affects the safety and performance of the road.

Examples & Analogies

Imagine a well-manicured lawn where a path forms over time due to foot traffic. The grass may get flattened where people walk, and no matter how much you water or fertilize, that flat area does not return to its original pristine state. Similarly, rutting is like that worn path on the road that stays depressed even after the weight is removed.

Mechanism of Rutting

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Caused by densification and shear flow in the mix.

• Dominant at high pavement temperatures.

Detailed Explanation

Rutting occurs primarily due to two mechanisms: densification and shear flow. Densification happens when repeated traffic loads compress the particles within the bituminous mix, causing them to settle more closely together, leading to a reduction in volume. Shear flow occurs when the material within the pavement begins to flow or deform under the pressure of the vehicles, particularly at higher temperatures where the asphalt becomes softer. Thus, rutting is more prevalent in warmer conditions when the pavement temperature rises.

Examples & Analogies

Think of a container filled with jelly beans (representing the aggregate in asphalt). When you press down on the top, the jelly beans become more tightly packed together (densification), and if you continue to press down, the jelly beans will start to squish and squeeze outwards (shear flow), creating grooves in the surface. That’s how rutting forms on a road: it’s the squished and settled materials due to traffic pressure.

Factors Affecting Rutting

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Binder type and grade.

• Aggregate gradation and angularity.

• Compaction quality.

• Pavement temperature and thickness.

Detailed Explanation

Several factors influence the occurrence and extent of rutting in asphalt pavements. The type and grade of binder can affect the material's viscosity and temperature susceptibility. For example, a softer binder may lead to more rutting compared to a harder one. The properties of the aggregate used in the mix, such as gradation (the range of particle sizes) and angularity (how sharp or rounded the particles are), also play a critical role in load-bearing and deformation resistance. Additionally, how well the pavement was compacted during construction impacts its ability to resist deformation. Lastly, environmental conditions, such as high temperatures and the thickness of the road layer, are significant, as warmer temperatures make the asphalt softer and more prone to rutting.

Examples & Analogies

Consider baking a cake: if you use all-purpose flour (a binder) instead of cake flour (a better, lighter binder), the cake might not rise well and could collapse (similar to poor rut resistance). If you compact the batter (the mix) properly, the cake will hold together better, much like a well-compacted road resisting rutting. And just as heat from the oven makes the cake rise and change texture, high temperatures can weaken the asphalt, leading to more ruts like a cake collapsing when it’s not made with the right ingredients.

Rutting Resistance Testing

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Wheel Tracking Test (Hamburg Wheel Tracking).

• Repeated Load Triaxial Test.

• Dynamic Creep Test.

Detailed Explanation

To evaluate how well different asphalt mixes can resist rutting, several tests are performed. The Wheel Tracking Test simulates the effect of traffic loading on the pavement by rolling a weighted wheel over a specimen of the mix to measure surface deformation. The Repeated Load Triaxial Test investigates how the material behaves under cyclic loads and assesses permanent deformation. The Dynamic Creep Test focuses on measuring the permanent strain as the sample is subjected to repeated stresses. These tests help engineers determine the best mix design for optimal performance and longevity.

Examples & Analogies

Imagine testing the durability of ice cream cones by subjecting them to pressure from hands and ice cream scoops. The cones (asphalt mixes) would be tested to see how much they hold their shape when squeezed. Each test informs the cone manufacturer (engineers) how to adjust the cone recipe (mix design) so it can withstand being filled with ice cream (traffic loads) without collapsing (forming ruts).

Key Concepts

-

Rutting: The permanent deformation that occurs due to traffic loading.

-

Permanent Deformation: The lasting change to the shape of the material under load.

-

Factors Affecting Rutting: Includes binder type, aggregate characteristics, compaction, temperature, and thickness.

-

Rutting Resistance Tests: Methods used to evaluate mix performance against rutting, including Wheel Tracking Test and Dynamic Creep Test.

Examples & Applications

A highway experiencing rutting that leads to water pooling and hazardous driving conditions due to accumulated wheelpath deformation.

A comparison of two asphalt mixes, one designed with higher-quality aggregates that show increased resistance to rutting compared to a lower-quality mix that fails quickly.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When the wheels tread, and the heat is high, rutting forms, oh me, oh my!

Stories

Imagine a heavy truck that drives daily over the same spot in a road. Over time, the asphalt begins to wear down and create tracks, showing how rutting happens due to repetitive loading.

Memory Tools

To remember what affects rutting, think B.A.C.T.: Binder, Aggregate, Compaction, Temperature.

Acronyms

DPS - Densification, Permanent deformation, Shear flow helps to remember rutting mechanisms.

Flash Cards

Glossary

- Rutting

Permanent longitudinal deformation in pavements due to accumulated stress from traffic loads.

- Densification

The process where the volume of a material decreases under pressure or loading, leading to compaction.

- Shear Flow

The deformation of a material when a shear force is applied, causing it to flow.

- Wheel Tracking Test

A laboratory test that evaluates the rutting resistance of asphalt mixes under simulated traffic conditions.

- Dynamic Creep Test

A test that measures the deformation of a material when subjected to repeated dynamic loading.

- Triaxial Test

A test that assesses the mechanical behavior of materials under different stress conditions.

Reference links

Supplementary resources to enhance your learning experience.