Rheological Properties of Bituminous Mixes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

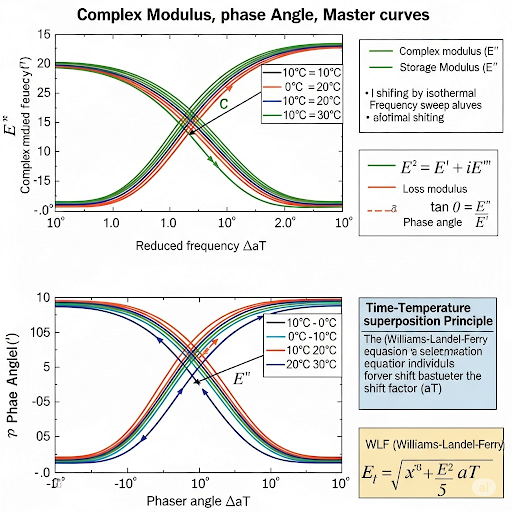

Complex Modulus and Phase Angle

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we’re going to talk about rheological properties of bituminous mixes. First, let’s discuss the complex modulus. Does anyone know what it indicates?

I think it has something to do with how stiff the material is, right?

Exactly! The complex modulus shows us the stiffness of the material under dynamic loading. It incorporates both the elastic and viscous components. Now, what about the phase angle?

Is the phase angle how we understand the balance between those components?

Great connection! A lower phase angle indicates a more elastic behavior, while a higher phase angle suggests a more viscous response. Can anyone recall why this distinction is important?

It helps in understanding how bituminous mixes will behave under different conditions, right?

Exactly! By knowing how these properties relate to performance, we can better predict and improve mix designs.

Let’s summarize: the complex modulus quantifies stiffness, while the phase angle indicates the material's viscoelastic behavior. Understanding these helps in designing better pavements!

Master Curves

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss master curves. Who can explain what a master curve is?

Isn’t it a graph that shows the modulus of a mix at different temperatures?

That's correct! Master curves plot modulus versus frequency over a range of temperatures. Why do you think these curves are useful?

They help in predicting how a mix will perform under real-life conditions without testing every temperature?

Exactly! This can save time and resources during the design phase. When we have this data, we can tailor our mixes to withstand specific environmental stresses. Can anyone give an example of where this might be important?

Maybe in designing pavements that will be used in different weather conditions faster and more effectively?

Exactly! Efficient prediction of performance is vital for ensuring the durability and safety of roadways.

To summarize, master curves are essential for analyzing and predicting the behavior of bituminous mixes at varying temperatures and loading conditions!

Time-Temperature Superposition Principle

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's discuss the Time-Temperature Superposition Principle. Who can tell me what this principle implies?

It suggests that we can predict how a bituminous mix will behave over a long duration using shorter duration tests, right?

Correct! This principle allows us to create models that extrapolate performance predictions from short-term tests. Why is this beneficial?

It makes testing more efficient since we don’t have to wait for long periods to see results?

Yes! And it helps accelerate the evaluation process, which is crucial in pavement design. Can anyone think of a scenario where this would be useful?

In projects with tight deadlines, having quicker predictions can help in making immediate decisions on material choices.

Absolutely! This principle is vital in efficient pavement design and contributes to better roadway performance. Let’s review what we learned: This principle allows for shorter test durations, providing crucial predictions for long-term behavior.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains rheological properties essential for understanding how bituminous binders behave under stress. Key concepts like complex modulus, phase angle, master curves, and the time-temperature superposition principle are introduced to analyze performance in real-life conditions.

Detailed

Rheological Properties of Bituminous Mixes

Rheology is the study of deformation and flow in materials, which in the context of bituminous mixes involves examining how bituminous binders behave under stress to understand their performance in flexible pavements. This section highlights essential rheological properties including:

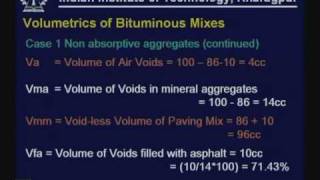

- Complex Modulus and Phase Angle: Measured using a Dynamic Shear Rheometer (DSR), the complex modulus represents the material’s response, while the phase angle differentiates between the elastic (storage) and viscous (loss) components of the material's behavior.

- Master Curves: These plots of modulus versus frequency over a range of temperatures allow for modeling the expected performance of mixes under various conditions, enabling better design and analysis of pavement mixtures.

- Time-Temperature Superposition Principle: This principle aids in predicting a mix's behavior over long periods based on short-term test results, facilitating efficient evaluation of performance across a span of operational conditions.

Overall, understanding these rheological properties is vital for engineers to design bituminous mixes that meet performance expectations under varied environmental and loading conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Rheology

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Rheology is the study of deformation and flow of bituminous binders within the mix.

Detailed Explanation

Rheology is a branch of science that focuses on how materials deform (change shape) and flow (move) when force is applied. In the context of bituminous mixes used in road construction, understanding rheological properties enables engineers to predict how these materials will behave under pressure and heat, which is crucial for ensuring the durability and functionality of roads.

Examples & Analogies

Think of rheology like observing how honey flows on a warm day compared to a cold day. When honey is warm, it flows easily, and when it’s cold, it becomes thick and slow-flowing. Similarly, bituminous binders change their flow properties based on temperature and the forces acting on them.

Complex Modulus and Phase Angle

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Measured using Dynamic Shear Rheometer (DSR).

• Indicates elastic and viscous components.

Detailed Explanation

The complex modulus is a measure of how a material responds to stress and strain, particularly how it behaves both elastically (like a spring) and viscously (like syrup). This is determined using a device called the Dynamic Shear Rheometer (DSR), which applies stress to the bituminous sample and measures its response. The phase angle quantifies the time lag between the applied force and the reaction of the material, which helps engineers understand how much of the material's response is elastic versus viscous.

Examples & Analogies

Imagine playing with a rubber band. If you stretch it and it returns to its shape, it shows elastic properties. However, if you put pressure on a puddle of syrup, it slowly spreads without bouncing back. The rubber band's stretching and the syrup's spreading are similar to the elastic and viscous behaviors of bituminous mixes.

Master Curves

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Plot of modulus vs. frequency over a range of temperatures.

• Used to model performance under real-life conditions.

Detailed Explanation

Master curves are graphical representations that show the relationship between the modulus of a material and the frequency of loading it experiences, at various temperatures. By analyzing these curves, engineers can predict how bituminous mixes will perform over a wide range of temperatures and loading conditions—not just under the specific conditions they test. This allows for better design and utilization of materials in pavement construction.

Examples & Analogies

Think of a master curve like a weather forecast that tells you what to expect in different seasons. Just as a forecast helps you plan for sunny or rainy weather throughout the year, master curves help engineers anticipate how road materials will behave under different conditions.

Time-Temperature Superposition Principle

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Enables the prediction of mix behavior over long durations using short-term tests.

Detailed Explanation

The Time-Temperature Superposition Principle is a concept that helps predict the long-term behavior of bituminous mixes based on short-term tests. It states that the effects of temperature can be shifted along the time axis, meaning that what we see in short-term tests at higher temperatures can be related to longer-term behavior at lower temperatures, thus allowing for efficient testing and analysis.

Examples & Analogies

This principle is like knowing that a cake, when it sits out longer at room temperature, will eventually ‘settle’ and change its texture. When baking, we can quickly test a small piece at high heat, but we still understand how it will behave when cooled over time. In the same way, engineers can use short-term tests to estimate long-term performance.

Key Concepts

-

Rheology: The study of how materials deform and flow under stress.

-

Complex Modulus: Represents the stiffness of bituminous mixes under dynamic loading.

-

Phase Angle: Indicates the balance between elastic and viscous responses.

-

Master Curves: Graphical tools for predicting material performance across temperature and frequency.

-

Time-Temperature Superposition Principle: Allows predictions of long-term behavior from short-duration tests.

Examples & Applications

Master curves can be generated from lab tests to forecast how a specific asphalt mix will perform throughout different seasons, allowing engineers to optimize design strategies.

The dynamic shear rheometer can quickly give insights into the complex modulus and phase angle of a binder, informing decisions about its suitability for a specific application.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Complex modulus and phase angle play, help predict the pavement's way.

Stories

Imagine a bridge made of bitumen, performing in heat and rain - the complex modulus lets it stand tall, while the phase angle ensures it won’t fall.

Memory Tools

For Rheology, remember 'C-PMT' – Complex modulus, phase angle, Master curve, Time-temperature superposition.

Acronyms

RHEO

Rheology Helps Engineers Optimize performance.

Flash Cards

Glossary

- Rheology

The study of deformation and flow of materials under applied forces.

- Complex Modulus

A measure of the stiffness of a viscoelastic material, combining its elastic and viscous responses.

- Phase Angle

A metric indicating the lag between stress and strain in a viscoelastic material, reflecting the balance between elastic and viscous behaviors.

- Master Curve

A graphical representation of a material's modulus over different temperatures and frequencies, used for predicting performance.

- TimeTemperature Superposition Principle

A principle allowing for the extrapolation of long-term material behavior from short-term test results by adjusting for temperature effects.

Reference links

Supplementary resources to enhance your learning experience.